Watch the Mosaic Xplor conduct fast, accurate 3D scans of difficult-to-reach environments.

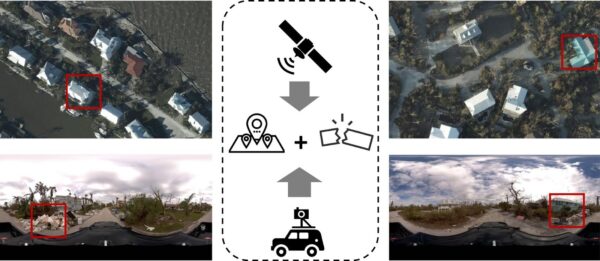

MERO is an important piece of the EU’s critical energy infrastructure and holds the Czech Republic’s national strategic crude oil reserves. Having an accurate digital representation of the facilities is important for maintaining the high levels of security, cleanliness, and safety. To perform reality capture, the Mosaic team took a trip to the MERO facilities with the Mosaic Xplor backpack MLS system. They captured tight indoor environments, outdoor yards with storage containers, and even climbed stairs with the Xplor, scanning the entire scene.

In this conversion, Jeffrey Martin, Mosaic CEO, interviews Pavel Janouškovec, Head of Operations at MERO. They discuss the importance of routine, accurate 3D scans for crude oil storage facilities and how Xplor makes the process faster and easier.

MERO Interview

Jeffrey: Hi everybody! We are here in Nelahozeves, Czech Republic, at the Mero crude oil storage facility with Pavel Janouškovec. Hi, Pavel. So, what is this place?

Pavel: Now, we are under the central tank farm, in which we hold the national strategic crude oil storage for the Czech Republic and the capacity for both refineries for normal operation.

Jeffrey: So, how much crude oil is here? I see many, many tanks. How many tanks are there?

Pavel: Now, on the central tank farm, it has 17 tanks of different capacities. The general amount of crude oil is 1,650,000 tons.

J: Okay, that sounds like a lot of crude oil. This is the strategic reserve? How much time would that last for the Czech Republic?

P: Yes, most of this amount of crude oil is for the national strategic reserve, and the crude oil is in here for 15 to 16 years at the oldest, but now we are changing it a little bit.

J: And how much time would this crude oil take to be used in the case of an emergency?

P: The Czech Republic has a strategic reserve for 3 months. We have had crude oil for nearly 2 months, and the rest of this reserve is in production.

J: It’s quite a large place with a lot of pipes and equipment. I guess you need to spend quite a lot of effort to maintain it and to make sure that it is functioning properly?

P: Yeah, sure. We are doing the maintenance on the pipeline for intelligent pics and, of course, we maintain the tank. Every 20 years, we totally reconstruct it with scanning, emptying, cleaning, etc.

J: You have to do some 3D scanning for the general documentation?

P: Yes, of course. The documentation for us is absolutely important as a base, and we are doing the 3D scans. We have the laser technology, and we have the cameras, and it’s absolutely important for us for the production, maintenance, and investment of all these devices.

J: So I guess there are lots of different ways to do 3D scanning depending on how much detail you need. Sometimes you need millimeter accuracy.

P: Yeah, sure. That’s why we are using different technologies for 3D scans. For the most precise, there are laser 3D scans, but, of course, it takes lots of time and a higher amount of money. For us, it’s most precise, but we are using different scans as well.

J: Sometimes, for maximum accuracy, you can use a terrestrial laser scanner, but other times it’s easier to do a much faster scan that gives centimeter accuracy.

P: Which are very useful for, say, documents like technological instructions or orders. We are also using it for our employees, explanations of what to do, how to do it, and where to do it.

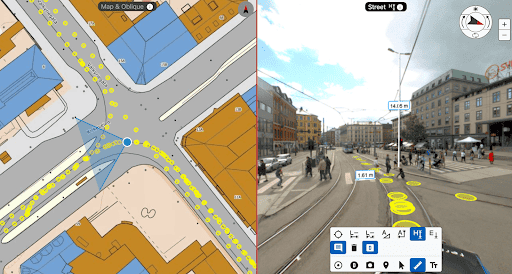

J: The way that we’re scanning today with the Mosaic Xplor it’s mounted on a backpack. It can be done on a bicycle or on foot. This is easier and beneficial for you guys in certain scenarios?

P: Yes! It’s very helpful, and it’s easier for us. I can imagine that these results will be used for inspection. Additionally, normal people can do it, so yeah, it’s very useful.

J: How much faster is it to scan on a bicycle compared to using a tripod? I guess it takes many hours?

P: We cannot compare because with laser scans we can scan for a large amount of hours. We can say it’s 10 times faster, maybe more.

J: Thanks a lot, Pavel, for inviting us here to see this interesting place. It’s great to see what you guys do and how it all works.

P: Yeah, of course. You are welcome.

J: Thanks a lot.

P: Thank you very much.

Full video

Watch the interview here, accompanied by visuals on our YouTube Channel, where you can see tutorials, case studies, and more.