New workflows, new dimensions of engagement and collaboration across the construction teams throughout the lifecycle of a construction project.

Reality capture in the AEC industry

In the AEC (Architecture – Engineering – Construction) industry, accurate data and precise measurements of physical elements are essential which is why the AEC segment has seen a growing trend towards reality capture technologies. While traditional methods of measuring and documenting a building or a construction site, such as using a tape measure or relying on hand-drawn plans worked for a long time, they cannot compare to the range of benefits associated with being able to get a precise 3D representation of whatever stage the construction project finds itself at – from collecting spatial data to facilitate project planning, monitoring the construction progress to visualizing the final project to fully perceive its added value.

How do you capture reality in the AEC industry

As the name suggests, reality capture refers to the process of collecting and processing data from the physical world to create a digital model or representation of it. This data can be collected through various means such as 3D scanning, photogrammetry, LiDAR, or structured light scanning or their combination. The technique utilized depends on the level of accuracy and detail that is expected from the outset. LiDAR uses laser pulses to create highly detailed 3D maps of an environment including centimeter–precise point cloud representations of assets and surrounding landmarks. Photogrammetry uses high-definition photographs captured from different angles to create accurate 3D models. Their combination, LiDAR integrated 360º camera,allows getting a precise, geo-referenced, image-like digital twin of the surveyed area and all the assets in it.

Reality capture benefits package for AEC industry

The range of efficiencies that reality capture tools can bring to the AEC industry is unquestionable. Let’s see what 3D modeling has to offer to architecture, engineering and construction businesses and authorities.

Accelerated surveying to facilitate project planning

Unparalleled speed of data capture and amount of data processed allows surveyors and planners to create ultra-precise, geo-referenced and scaled 3D models of existing environments which can significantly reduce the time (and cost) required for traditional surveying methods. In addition to speeding up the surveying process, reality capture tools also enable project teams to visualize and analyze data in new ways. As-built 3D models generated by these tools can be used to simulate different scenarios, test design concepts, and identify potential issues before construction begins. This helps to minimize risk and improve project outcomes by ensuring that designs are feasible and meet project requirements.

Reality capture as a bridge to BIM

When it comes to planning, design, and construction of buildings, BIM (Building information modeling) is a standard and an obligation across the world. It refers to a highly collaborative process that allows architects, engineers, real estate developers, contractors, manufacturers, and other construction professionals to plan, design, and construct a structure or building within one 3D model. Reality capture forms a connection between raw site conditions and an intelligent BIM environment which ensures that the BIM model reflects the real-world environment accurately and increases engagement across all project stakeholders.

Designing and building in the context

High–definition 3D images and models of the surrounding environment like natural landmarks, traffic situations, etc. created by reality capture tools allow construction professionals to visualize the construction in a very precise context. This helps project teams to better understand the relationship between the building and its surroundings, enabling them to make more informed design decisions, to identify potential clashes and conflicts between the construction design and the real-world environment, such as interferences with existing infrastructure or surrounding nature. This allows project teams to make adjustments to the design early in the process, reducing the risk of errors and rework significantly.

“The truly game changing aspect of a digital twin is that it has the capacity to bring together building information from a wide range of sources. That and the ability to build customised solutions that solve specific business problems, will not only deliver a 360O view of the building through one user interface, but also help optimize its performance through contextual presentation of data and automated analytics.”

Claire Penny, Global Digital Evangelist at Invicara (source)

Digital twins of objects for renovations

When the context of an architectonic project is as narrow as an existing building, construction or even a whole road infrastructure that needs to be extended or renovated, the need to have accurate data and precise measurements of the object along with a lot of details about its condition, materials used, etc. can even increase, especially if the available documentation is not sufficient or simply not available. Photo-to-point cloud models of objects before reconstruction have been changing and creating new workflows, decreasing the amount of manual effort, and reducing the trips to the construction site.

“A digital twin is more intuitive than facility management software in terms of inspecting and updating detailed information associated to building components or spaces. For example if a faulty faucet is replaced with a new product, product information in the digital twin must be also updated.”

Valentin Velinov, Development Manager, BIM and Digital Services at Skanska (source)

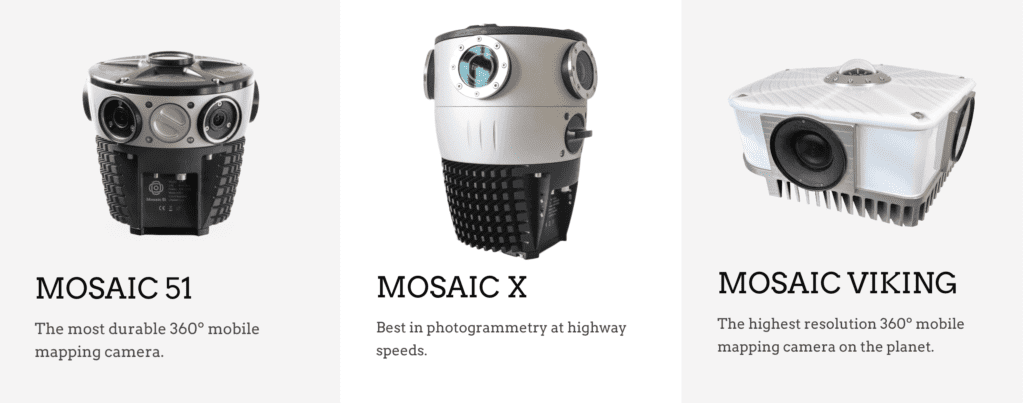

With high-definition mobile mapping technologies available today among which Mosaic is proud to offer best-in-class solutions, the scale of 3D modeling has pretty much no limits, as for example the recent success story of Dymaxion shows. This case stars the Mosaic 51, a 360 – degree camera inspecting and documenting the condition of thousands of kilometers of Colombian motorways to create a supporting documentation for a large-scale project of their extension.

Monitoring the construction progress

When it comes to monitoring the progress of the construction project, the key to increase the efficiency is simply reducing the field trips. Rather than sending out a comprehensive team of engineers and quality assurance officers throughout a lengthy construction project that may last several years, the Mosaic 360 cameras for engineering firms can provide the same information, at a much reduced cost and from a more convenient environment. Using reality capture throughout the construction project is a simplified way to compare the as-built conditions to the design plans and allows the construction teams to identify any deviations or discrepancies and take corrective action as soon as possible.

Reality capture and digital twins in facility management and maintenance

To be able to plan the facility maintenance strategically, having precise knowledge and (more importantly) documentation of every detail of its condition is the key. Being able to get a photogrammetric model (complemented by LiDAR data when necessary) allows weeks of work of entire asset inspection teams to be reduced to days. It also reduces the error rate related to manual work to a minimum and very importantly enhances modern maintenance strategies such as controlled aging or asset simulation.

Of course, there are limitations, but…

Although the potential of reality capture technologies in the AEC industry has been growing together with its use, it still has some ways ahead to overcome its common limitations. This includes the cost and LiDAR scanners and photogrammetry software which can be a barrier for some smaller AEC firms or construction projects with limited budgets.

It is also widely embraced that structured data acquisition using a photographic survey and 3D data reconstruction requires specialized knowledge and training to operate effectively, interpret the data collected, and create accurate digital models in post processing.

Naturally, some of the limitations are associated with the technology itself or/and with the environmental factors and can impact the accuracy of the data captured through 360 – degree cameras or LiDAR scanners, such as harsh weather or poor lighting conditions due to natural obstacles, reflective surfaces.

…We got this

Among other things, it is these limitations that inspire us at Mosaic and move us forward in the development of both hardware and software solutions for 3D surveying for AEC industry, which is why Mosaic 360 cameras offer:

- 12K, 13K, and 22K HD resolution – highest in the market

- Easily manageable and single manned operation with minimal training

- Image data capable of high-quality 3D models and textured meshes

- Photorealistic environments

- Easy point cloud colorizing (when integrated with LiDAR)

- Robust industrial frame & connectors to withstand the cold, the heat, water, dust, poor road conditions

- Non–vendor locked data

With mobile surveying solutions for AEC industry by Mosaic 360–degree cameras, that allow fast and centimeter – precise 3D modeling, there is pretty much no limit to the scale of the surveying project, no matter whether it is a future or existing construction site, a building for renovation or entire neighborhood, or hundreds of kilometers of road infrastructure.

The future of 360º cameras in AEC industry is now

The development of reality capture technologies (not only) for the AEC industry runs at a steady pace towards automation and usage of artificial intelligence that is expected to increase in the coming years as well as towards more flexibility and accessibility in data capture process through the advancement of mobile devices. Reality capture data integration with BIM is expected to continuously improve to provide an even more complete picture of the construction project and allow for better decision-making throughout the project lifecycle. Together with the increase of cloud-based reality capture platforms the development aims at anywhere, at any time and from any device collaboration. So, there’s not much time to hesitate to explore what 3D surveying can bring to your construction project if you don’t want to miss the train. In terms of development, we are definitely not going to stay behind.

Overall, reality capture technologies like 360º cameras, photogrammetry or LiDAR scanning have been bringing completely new workflows to construction projects at all their phases, enriching the AEC industry with a more accurate, efficient, and collaborative approach, leading to better outcomes for all stakeholders involved. Visualizing a point cloud and placing it in a photorealistic and geo-referenced environment allows unparalleled collaboration and interaction throughout the construction project which significantly reduces the field trips, personnel costs and risk of reworks, but also helps to create a safer work environment. If you would like to learn more about what surveying solutions Mosaic 360–degree cameras can offer to your construction project, contact us below via the contact form to get in touch.