Enhancing efficiency with Mosaic Camera Systems in Industrial Oil and Gas Pipeline Management

Discover how Mosaic imaging solutions are simplifying pipeline management for oil and gas companies through:

- Advanced technology for comprehensive pipeline oversight

- Technological integration for efficient pipeline design and construction

- Successful collaboration and integration

Introduction

Companies face numerous challenges when it comes to checking and maintaining oil and gas pipelines, particularly those with limitations in capturing and monitoring elements above the ground across interconnected networks.

With this the need for reliability and safety of energy networks hinges on effective pipeline management on industrial operation. Addressing the complexities of these hidden networks requires innovative solutions.

In this article, let’s explore how Mosaic mobile mapping camera systems are changing the game for industrial oil and gas companies.

From the detailed work of planning new networks to the essential task of investigating current routes, Mosaic imaging solutions’ advanced technology proves to be a game-changer, making complex tasks simpler and ensuring efficiency down to every detail.

The Changing Face of Pipeline Management

Maintaining and expanding pipeline networks poses challenges for energy providers including those in oil and gas and even electrical companies. Conducting thorough audits and inspections is vital to ensure the pipelines’ integrity and functionality.

The year 2024 brings advancements in camera technology, specifically in mobile mapping cameras, offering accurate and efficient solutions for oil and gas pipeline inspection.

To meet the growing needs of urban infrastructure, technology becomes crucial in streamlining the design, construction, and management of underground pipelines. Here’s how technology integration plays a vital role:

1. Pipeline Design with 3D Tech

Cutting-edge tech like Building Information Modeling (BIM) is changing how we design and plan underground pipelines. BIM gives designers a 3D virtual view, helping them see and analyze the system layout. This tool is crucial for placing pipelines better, avoiding issues, and making the system more efficient.

2. Real-Time Monitoring for Long-lasting Pipelines

On the operational side, integrating technology transforms real-time monitoring and maintenance. Sensors and IoT devices gather data on flow, pressure, and temperature in pipelines. This data goes to a control center, letting operators spot potential problems early and do proactive maintenance. This means fewer disruptions, making the underground pipeline network last longer.

3. Tech Integration for Maintaining Resilient Pipelines

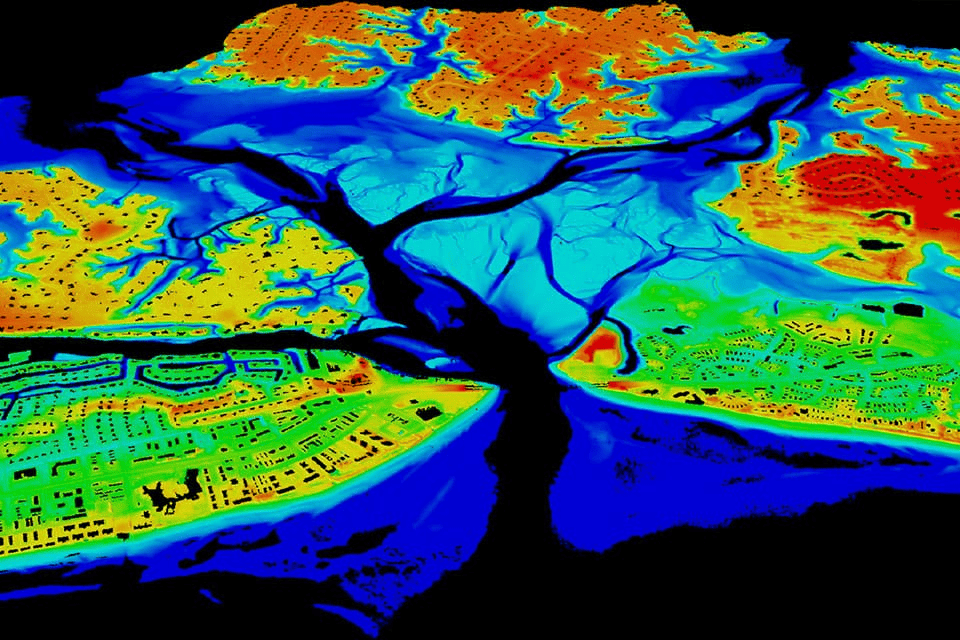

In construction and installation, tech integration is key to streamlining processes. Geographic Information System (GIS) tools map and manage underground infrastructure to maintain an up-to-date view of the current infrastructure including where it is located, the more recent conditions, and other metadata.

Through the use of various remote sensing devices, ground-penetrating radar, mobile mapping cameras and LiDAR, end users of the data can make more informed decisions about their assets and be more prepared for scheduled maintenance needs or by reducing the risk of damage during construction.

This integrated approach makes installation, maintenance and construction more efficient, creating a smoother and stronger underground pipeline network.

Mosaic Imaging Solutions: Pioneering Imaging Solutions Provider

Transitioning from the intricate world below ground to the dynamic realm above, Mosaic mobile mapping camera systems lead the way in large-scale, street view image capture, providing oil and gas companies with advanced solutions for pipeline management.

Working as standalone units or integrating cutting-edge camera technology such as LiDAR, and other geospatial technology, Mosaic camera systems stand out as a comprehensive tool for tackling the industry’s multifaceted challenges.

This transition from underground to street-level imagery is to guarantee the integrity and functionality of pipelines. Mosaic Imaging Solutions uses a 360-degree surveying method with mobile mapping cameras, giving a complete view of pipeline conditions, in ways large and small.

By capturing what is above the current existing pipelines or future pipelines at ground level grants great value to the teams tasked with building, managing and maintaining such systems. Having (near) real-time data at their fingertips to explore before visiting a site to see what is currently there at ground-level allows them to make better decisions about what vehicles and tools they need to bring for their next maintenance job. It also allows them to monitor vegetation growth around their pipeline networks over time.

Mosaic 51 and Mosaic X – Bridging the Gap with GIS

Geographical Information Systems (GIS) play a crucial role in making data tangible and visible through map creation, addressing vital questions regarding spatial locations and features. The Mosaic 51 and Mosaic X, are innovative tools, which aid surveyors and organizations in acquiring high-resolution imagery and geospatial data essential for infrastructure plans, construction, and maintenance.

Mosaic 51 and Mosaic X’s groundbreaking method of capturing images and data ensures GIS users can have the most current street view imagery on hand, offering accurate and real-time information.

This applies to various scenarios such as changing street conditions or monitoring road signs in areas prone to tropical storms or flooding.

Standalone Units or Customizable Mobile Mapping Systems

Both Mosaic camera systems are standalone systems that are equipped with storage, an integrated GNSS for GPS data, and onboard GPU+CPU for efficient onboard processing, making it a user-friendly solution that has a small footprint and can go anywhere..

Additionally, Mosaic camera systems can seamlessly integrate with external sensors to better meet the demands of the user or end user of the data. This includes external GNSS, INS, and LiDAR.

These integrations facilitate a clearer understanding of the ground reality where other assets are located, enabling easier and more efficient maintenance of the street view feature layer.

Audit and Inspection Made Easy

Effective pipeline management starts with detailed audits and inspections. Mosaic imaging solutions empower industrial energy providers, particularly in oil and gas, by offering a 360-degree surveying capability above ground.

By providing a comprehensive view of the route conditions and Right-of-Way surrounding the pipeline through mobile mapping cameras, audits and inspections can be systematically completed, documented and reviewed repeatedly.

Meeting the Underground Challenges

Energy providers face unique challenges in managing underground networks, such as electric and gas networks that span vast distances. Many of these networks are not “future-proof,” lacking the resilience needed for the evolving energy landscape.

Imagine an energy provider dealing with the complexities of managing extensive underground networks. These networks may not be resilient enough for the evolving energy terrain. Mosaic Imaging Solutions steps in, offering crucial insights during route investigation.

By assessing the visible landscape above the pipelines, including the state of the land, buildings, and potential obstacles, our technology helps surveyors and maintenance crews predict hazards and plan for access points with informed foresight.

Precision Engineering for New Networks

Energy providers, including oil and gas companies, tasked with engineering new networks, such as laying down tens or hundreds of kilometers of pipelines, require careful planning. Mosaic imaging solutions prove invaluable during route investigation, providing on-the-ground assessments of available space and potential challenges.

Consider an oil and gas company tasked with laying down 80 kilometers of new pipelines. The challenge is to carefully plan and engineer the new network. Mosaic mobile mapping camera systems provide a reliable and robust image solution during route investigation. The high-resolution, clear 360º street-level imagery collected can be used for ground assessments to ensure precise planning, addressing potential challenges efficiently.

360 Cameras for Effective Oil & Gas Pipeline Management

Mosaic’s 360 cameras play a significant role in pipeline management by offering detailed insights into above-ground conditions. Surveyors use their expertise to predict hazards and assess the surrounding environment, while Mosaic’s cameras provide essential visual data for informed decision-making and preparation.

This collaboration between surveyor knowledge and camera technology enhances pipeline management, enabling proactive measures and informed responses to potential challenges, ensuring the seamless operation and maintenance of pipelines.

Remote Inspection of Pipeline Roads

In surveying, challenges arise from manpower and traffic, impacting efficiency. Traditional methods involve extensive on-site hours and disrupt traffic flow. Mosaic’s camera systems overcome these hurdles by enabling remote inspection of pipeline routes.

By capturing conditions above ground, these cameras empower surveyors to predict hazards, understand the landscape, and plan access points effectively, eliminating the need for road closures and ensuring a smooth and informed surveying process.

By being able to capture large swaths of street level data in a single pass with a vehicle, surveyors and maintenance crews can view and inspection the conditions of the land above their pipelines or future pipelines, from the comfort of their offices rather than transversing hundreds of miles to see the assets and infrastructure in person.

This saves large amounts of time in the inspection of such large and vast areas of land. Additionally, the 360º imagery can be visited time and time again, as well as compared historically over time to see the change in conditions.

Conclusion

Mosaic Imaging Solutions, particularly the Mosaic 51 and Mosaic X, plays in revolutionizing pipeline management for industrial oil and gas companies. As the energy landscape evolves, the challenges of inspecting, maintaining, and expanding pipelines become increasingly complex. Mosaic Imaging Solutions address these challenges through an innovative approach, combining cutting-edge camera technology, LiDAR applications, and geospatial technology.

The 360-degree surveying capability provided by Mosaic Imaging Solutions proves to be a game-changer, offering a comprehensive view of the pipeline’s above-ground condition through mobile mapping cameras. This capability significantly improves audit and inspection accuracy for energy providers adopting Mosaic Imaging solutions.

Looking ahead, Mosaic camera systems will play a key role in future capabilities. Their versatility and impact not only innovate urban mapping but also provide essential tools for industrial oil and gas companies managing pipelines.

Contact our team today to learn more.